Explore More

Explore More

Discover how our eco-friendly and energy-efficient lighting solutions

are contributing to a brighter, greener future for all.

We have 7 sustainable manufacturing facilities, a sophisticated supply chain system, and cutting-edge technology, all of which enhance our production capabilities and enable fabrication of over 10 million fixtures annually, with an exceptional success rate of over 99.32%.

Our predominant future goal is to significantly contribute to the reduction of global energy consumption. Through sustainable manufacturing, we are taking steady steps towards this direction.

When I started this company, I had a clear vision of where IKIO stands with respect to the environment and understood that our responsibility goes beyond merely providing innovative lighting solutions. Innovation should always align with the greater good, and that precisely reflects in our manufacturing process.

In our factories, we strive to minimize our ecological footprint by employing eco-friendly practices and utilizing energy efficient technologies. Our dedication to sustainability is embedded in every aspect of our operations, ensuring that as we light the way for our customers, we also contribute to a greener, more sustainable world for future generations.

Targeted reduction of 15% in global energy usage through sustainable manufacturing by 2030.

We contribute to reducing global energy consumption and achieving sustainability through these four approaches:

All our manufacturing is done in-house, thanks to our vertically integrated infrastructure. By implementing lean management principles and eliminating middlemen from the equation, we can streamline our production to increase our operational efficiency.

We also maintain the highest product quality by implementing no-compromise quality control processes. With technology like spectrometer, thermal chambers, LCR meter, etc., with an exceptional success rate of over 99.32%, reducing waste immensely

We have also actively sought and established strategic distribution points across the US to enhance our logistical efficiency and reduce transportation distances (thereby minimizing overall carbon impact). Managing inventory better also helps in avoiding overstocking and spoilage and be more sustainable. .

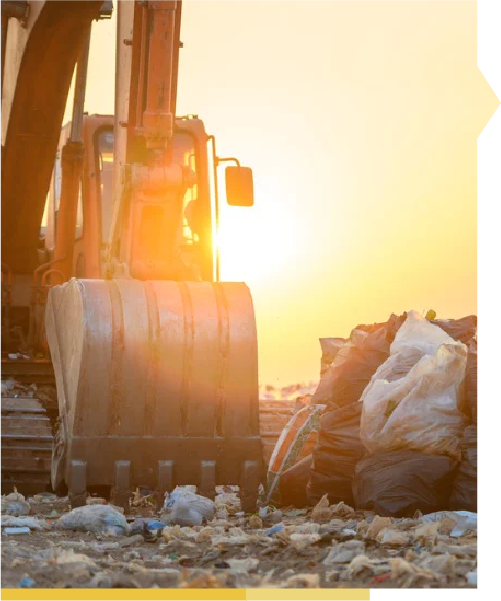

In addition, wherever it is economically feasible, we make sure that most of the materials are recycled and reused. We also have effective water recycling and storm-water systems in place to curb its wastage. Our Reuse-Reduce-Recycle policy diverts a major chunk of our waste from incineration, further adding to the cause of sustainability.

We use our in-house bulb crushers to crush existing lamps and bulbs. We then send them to our recycling partner, TerraCycle, an accredited and qualified recycling organization in the US. It recycles the mercury-containing luminaires as per the State and Federal Laws. Once recycled, we receive a certificate of recycling that can be provided to our partner should that be a requirement